FILAMENT POWER SUPPLY (FPS FLOATING POWER SUPPLY)

The filament power supply of the FPS series (floating power supply) complements the HPS high voltage power supply, also well known in the product range of the manufacturer ISEG. The FPS floating power supply is a regulated, stable current source, dedicated to filaments, often used in electron beam applications, such as EB PVD (Electron Beam Physical Vapor Deposition). EB PVD, is a form of physical vapor deposition in which a target anode is bombarded with an electron gun given off by a charged tungsten filament under high vacuum.

FILAMENT POWER SUPPLY – FPS FLOATING POWER SUPPLY SPECIFICATIONS:

- Floating power supply

- 1-channel filament power supply

- Standalone or used with an HPS high voltage power supply

- Fixed, positive polarity (+)

- Low voltage up to 30 V

- Current up to 50 A

- FIL- and FIL + floating and isolated outputs

- Voltage control by digital encoder

- Current control by digital encoder

- Voltage and current measurement by 2 * 8-digit LCD

- Safety interlock

- Programmable current ramp A / s

- LEMO connectors on rear panel or outputs by shielded cables

- Isolated USB and analog interfaces 0 – 10 V as standard

- RS232, CANbus, Ethernet interfaces optional

- Model L / W / H mm: 350 mm, Rack 19’’, 2U

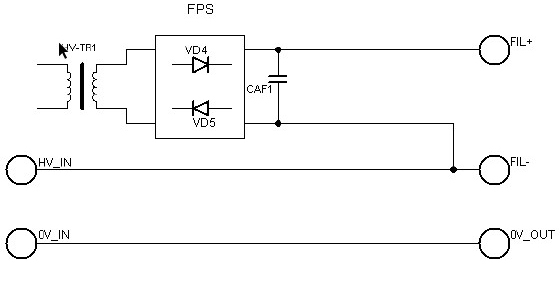

FILAMENT POWER SUPPLY : SCHEMATIC CABLING AND DIAGRAM

The filament power supply has a HV input connector allowing to connect the high voltage cable HV-in and 0V-in (sometimes called RETURN LINE) coming from the HV generator for the electron gun. The output of the floating power supply is made via a connector called ‘FIL- pole’ and another connector called ‘FIL + pole’. The FIL- pole is ‘hooked’ to the ‘hot spot’ HV-in of the HV power supply. The FIL + pole supplies the filament voltage, for example 12 V or 30 V depending on the model. The floating power supply is isolated from the ground.

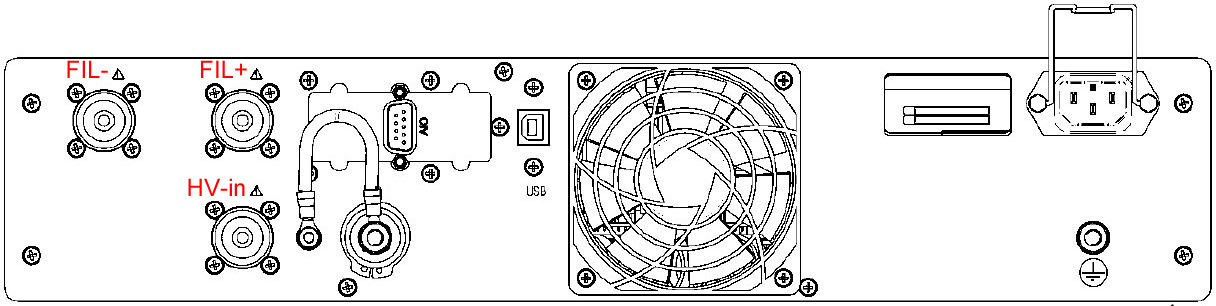

Rear Panel:

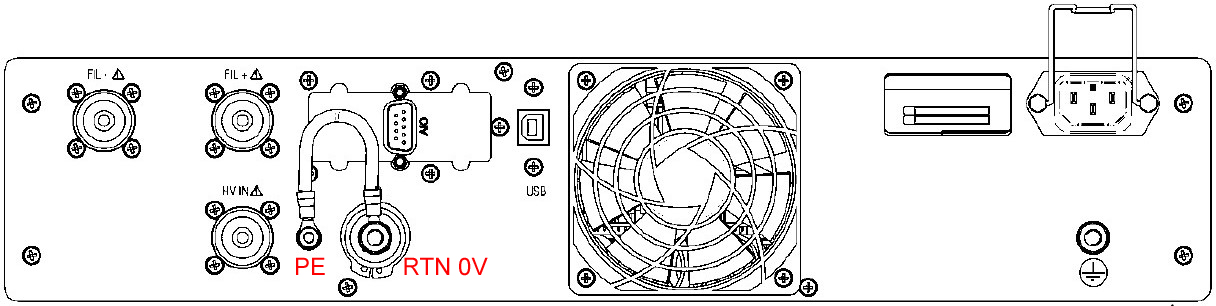

Rear Panel:

Wiring:

- PE: earth. power supply has a threaded rod / nut diameter M5 couple to ensure good quality grounding. The mechanical chassis of the FPS power supply is wired to earth for user safety.

- 0V-in (RETURN LINE): the ‘0’ volt ensures the continuity of the high voltage cable shielding coming from the external HV generator. The RETURN LINE pole is floating relative to PE earth. It can be connected to the PE using a short shunt cable accessible on the rear panel of the filament power supply. The potential between the RETURN LINE conductor and the PE earth is not monitored by the power supply. Therefore the user must ensure that this floating voltage is safe by knowing this voltage value.

The HV-in, 0V-in, FIL- and FIL + access of the filament power supply works in 2 ways at the rear:

- high voltage connectors types LEMO PSA.3S.CTA.C62 or others as per your request.

- shielded cables in the form of insulated and robust strands of adequate lengths.

Remote control:

Remote control:

The filament power supply is available from 30 W up to 600 W.

Upon request of our customers other versions can be produced by adapting the voltage and / or current. The mechanical size of the filament power supply is standard with a 19’’- 2U rack, allowing it to be placed in a 19’’ cabinet next to a electron gun power supply.

The resonance switching technology ensures a high level of efficiency, greater than 85%.

A motherboard with an embedded powerful processor (FPGA) allows this filament power supply supply to be interfaced in an advanced control – command process using any type of interface (USB, Ethernet, RS232, CANbus, analog AIO 0 – 10 V). the filament power supply is autonomous and the complete control via the front panel then becomes an option. Also we can offer it with a blank front panel, the command is then deported exclusively in remote mode.

As a more advanced version, we offer a front panel fitted with 2 rotary and digital encoders for fine voltage and current adjustments. Setpoint re-readings and voltage / current measurements are shown on 2 x 8-digit displays. The distinction between setpoint adjustment and measurement is visible by the blinking letter ‘S’ as in ‘settings’.

3 ‘push buttons’ allow actions such as On / Off, KillEnable (current regulation or current trip mode) and navigation menu comprising several programmable functions (current limit, current ramp, local or remote control, CANbus address, etc).

An extremely complete command set provides access to control registers which set flags and inform the user about the proper functioning of the filament power supply:

- a first register gives a reading on the state of the filament channel (IsVoltageExceeded, IsCurrentExceeded, isTripExceeded, IsExtInhibit, IsControlledVoltage, IsControlledcurrent, IsOn, IsRamping, IsInputError, etc),

- a second register gives visibility on the general state of the power supply (IsTemperatureGood, IsSupplyGood, IsModuleGood, IsEventActive, isSafetyloopGood, IsServiceNeeded).