HV POWER SUPPLY

The HV power supply in 19′ rack format is supplied by a single-phase or three-phase network voltage depending on the power and generates an output voltage up to 100 kVDC with powers options of 300 W, 800 W , 1500 W, 3000 W , 6000 W, and 10 kW.

HV high voltage power supply ‘1st generation’: this model was launched 20 years ago, it was ‘modernized’ in 2010. It received a new microcontroller, an intuitive front panel with access to numerous programmable parameters. It exists with 2 power ranges, 300 W and 800 W for a maximum voltage of 30 kVDC and 15 kVDC.

HV high voltage power supply ´2nd generation’: it has a very powerful FPGA processor which makes it possible to manage complex operations (ARC and ARCpro: ultra-fast electric arcs). The power supply exists with 4 large power ranges 1.5 kW, 3 kW , 6 kW,and 10 kW for a maximum voltage of 100 kVDC and 20 kVDC.

3 CONTROL MODES – POWER CONTROL

The HV power supply can be controlled in 3 different ways:

- a 9-pin SUB-D connector with analog and TTL signals (Vset voltage, Iset current, Vmon voltage monitoring, Imon current monitoring, On / Off, Inhibit, etc.),

- digital interfaces such as USB, CANbus, Ethernet, IEEE-488.

- a front panel with rotary encoders and multi-digit digital displays.

HV POWER SUPPLY PROPERTIES

- HV PS – 300 W – 10 kW, 1 kV – 100 kV

- 1 channel in 19” rack or compact box

- Excellent control characteristics

- LCD display and digital U / I encoders

- Multiple interfaces (as standard or optional)

- Management of electric arcs and short circuits

- VLN option: noise reduction <5.10 (-4) Vnominal

- HVS option: high voltage stability <1.10 (-4) Vnominal

- CLD option; capacitor charger

- ARCpro option: management of ultra-fast arcs

- ACL option: current limitation during an electric arc

- Operation Master – Slave for more power

- EOA option: extended power surface

- FCS option: integrated filament supply

- Option 2HC: 2 high voltage connectors for 2 outputs

- Option WR4: Input DC with 400 V – 480 V +/- 10% (6 kW and 10 kW)

Video tutorial & demonstration

- All ranges of HV power supplies from 300 W to 10 kW

- Industrial applications covered by 19′ rack power supplies

- Menu navigation using digital encoders

- Access to Configuration & Settings functions

- Presentation of the interfaces: Local & Remote mode

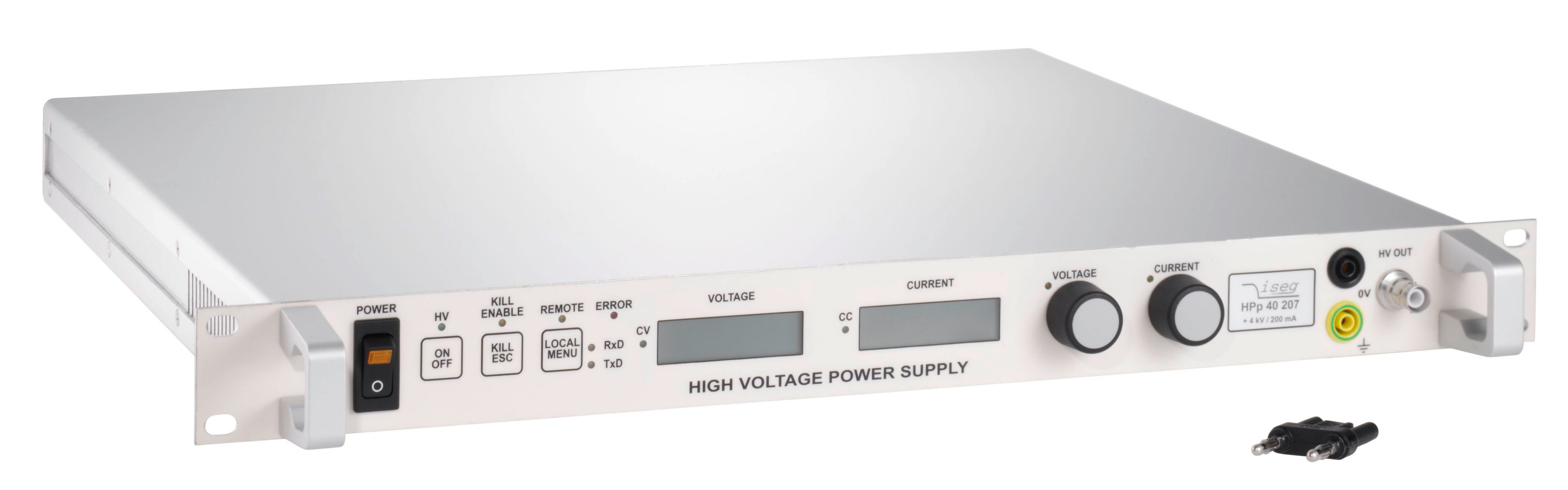

HV POWER SUPPLY ´1ST GENERATION’

The HV power supply has a height of 1U and is prepared to be mounted into a 19’ cabinet.

It offers a very high efficiency (> 85%) thanks to the resonance switching technology. The motherboard has a standard microcontroller which supervises the smooth running of operations, the programming of set points, the configuration of operating modes and the provision of various digital communication interfaces (USB, Ethernet, CANbus, IEEE 488, etc.).

The front panel of the HV power supply is equipped with 2 rotary and digital encoders for fine adjustment of voltage and current. It has two eight digit displays for voltage and current as well as for menu control.

Three push buttons enable the following functions: On / Off, KillEnable (current trip or current regulation mode) and menu for navigation with 10 programmable functions (voltage limit, current limit, voltage ramp, current ramp, auto start , auto AIF, set interface, set instruction, IEEE address, CANbus address).

Proven ARC function : after an electric arc, the high voltage output is inhibited for a short period (break time) so as to drain the energy stored in the filter capacitors. This helps to extinguish the arc. Once the energy discharge time has passed, the voltage is generated again, but via a linear ramp. The break duration and the voltage ramp time are a factory setting and cannot be programmed.

Thermal protection against temperature rise: the primary supply is cut if the power unit is overheated or if there is a reduced fan speed.

Constant current / trip current: the selection is done by the KillEnable button. In disable mode the output voltage will be limited after reaching the set current. In enable mode, the output voltage will be shut off permanently without ramp in case of current exceeding.

FLOATING GROUND AND COMMON GROUND MODE

The shield of the high voltage output is always connected to the housing (green-yellow PE-connector).

- If this shield is intended to use as “reverse line“, then a jumper has to be plugged between the ‘0 V’ (reverse current / black connector) and the “PE” connector.

- If this jumper has been removed, an additional “reverse line“ from the load to the “0 V“ connector must be used and this connector close to ground can float up to max. +/- 300 V. In this case the user is responsible that – due to the voltage between “0 V“ and “ PE“ connector – no danger for the user may occur.

If the potential between “0 V“ and “ PE“ connector is above 300V then – in order to avoid damages for the unit – the connections are short circuited with help of electronic protection circuits.

300 W AND 800 W RANGES

- Voltage from 1 kVOLT to 30 kVOLT

- Power of 300 Watts and 800 Watts

- Current from 10 mA to 800 mA

- 1-channel high voltage power supply

- Positive (+) or negative (-) polarity, fixed

- Common ground (GND) or floating +/- 300 V (jumper)

- Voltage control by digital encoder

- Current control by digital encoder

- Voltage and current measurement by 2 * 8-digit LCD

- Safety interlock

- Programmable voltage ramp up to 3000 V / s

- SHV connector on the front panel or LEMO connector on the rear panel

- USB and CANbus interfaces

- Isolated analog interfaces 0 – 5 V, RS232, IEEE 488 and Ethernet optional

- 19′ rack, 1U – 410 mm

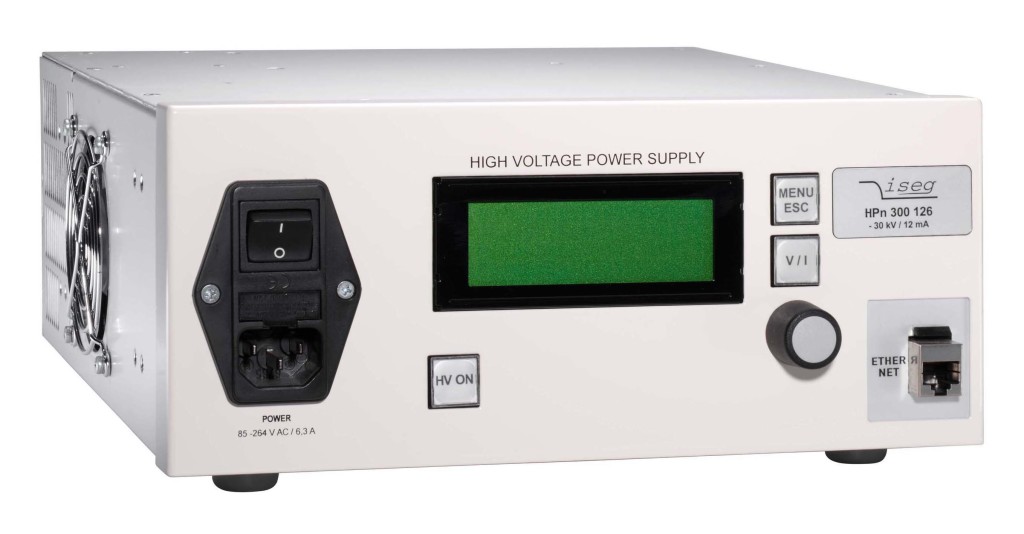

HV POWER SUPPLY ‘2ND GENERATION’

The new generation of HV power supply is offered with a powerful FPGA processor which manages complex operations. It exists in 19’ / 2U, 19’ / 3U and 19′ / 4U sizes to be integrated into a power cabinet. It offers patented resonance switching technology with very high efficiency (> 93%). The motherboard supervises the smooth running of operations, the programming of set points, the configuration of the operating modes and the provision of various digital communication interfaces (USB, Ethernet, CANbus, IEEE 488, etc.).

MANAGEMENT OF ELECTRIC ARCS WITH THE ‘2ND GENERATION’ MODEL

The HV power supply is equipped with an ARC management with adjustable parameters. An ARC is defined as a negative voltage slopewith a dv/dt greater than 0.1.Vnom/μs.

After an ARC is detected, the control signals of the inverter are blocked within some μ-seconds for the pausing time called ARCwait At the same time, the internal set value for the output voltage is set to 0 V At the time instance t = t1, the internal set value of the output voltage is increased with the voltage ramp (ARCramp).

Detected ARCs are counted. If a predefined number of ARCs (ARC number) is detected within a predefined time (ARCTime), this will be treated as an error (ARC error) and the high voltage generation will be stopped.

- ARC-wait (100 ms -> 6 s),

- ARC-number (0 – 99),

- ARC-time (100 ms -> 10 s),

- ARC-ramp-time (100 ms -> 4 s).

These data are programmable via the local menu or remotely and are managed by the processor firmware which performs the calculation tasks.

1500 W AND 3000 W RANGES

- Voltage from 1 kVOLT to 100 kVOLT

- Power of 1500 Watts and 3000 Watts

- Current from 15 mA to 3 A

- 1-channel high voltage power supply

- Positive (+) or negative (-) polarity, fixed

- Common ground

- Voltage control by digital encoder

- Current control by digital encoder

- Voltage and current measurement by 2 * 8-digit LCD

- Safety interlock

- Programmable voltage ramp up to 3000 V / s

- SHV connector on the front panel, LEMO or GES connector on the rear panel

- Isolated USB and analog interfaces 0 – 5 V as standard

- SPS analog interface (0-10 V analog + 24 VI / O logic) as an option

- RS232, CANbus, IEEE488 and Ethernet interfaces as an option

- Model L / W / H mm: 410 mm & 550 mm, Rack 19”, 2U – 3U – 4U

6 KW AND 10 KW RANGES

- Voltage from 1 kVOLT to 20 kVOLT

- Power of 6 kWatts and 10 kWatts

- Current from 300 mA to 10 A

- 1-channel high voltage power supply

- Positive (+) or negative (-) polarity, fixed

- Common ground

- Voltage control by digital encoder

- Current control by digital encoder

- Voltage and current measurement by 2 * 8-digit LCD

- Safety interlock

- Programmable voltage ramp up to 3000 V / s

- LEMO or GES connector on rear panel

- Isolated USB and analog interfaces 0 – 5 V as standard

- SPS analog interface (0-10 V analog + 24 VI / O logic) as an option

- RS232, CANbus, IEEE488 and Ethernet interfaces as an option

- Model L / W / H mm: 500 mm, Rack 19”, 4U

HV COMPACT HIGH VOLTAGE POWER SUPPLY

The HV Compact high voltage power supply is available with dimensions of 280 * 254 * 107 mm and with the power of 350 W. A large multi-line LCD screen with 1 digital push button encoder and a menu button allow the adjustment of 7 functions such as voltage and current, high voltage and current limits, selection of KillEnable / KillDisable mode (current trip / current regulation) or the voltage ramp (800 V / s) and current ramp (200 mA / s). The set point measurements and the voltage / current measurements are also made via the display, the distinction between the two being made by a small ‘*’ (asterisk) to the left of the numerical values. The supervision of the tasks makes it possible to activate the alarms and to detect faults in order to inform the user on the actions to be carried out:

- Error safetyloop,

- Error overtemp,

- Error trip,

- Error inhibit,

- Real time clock error,

- Contact service

ARC MANAGEMENT WITH HV ‘COMPACT’ POWER SUPPLY

The HV ‘Compact’ high-voltage power supply is equipped with an ARC management system with adjustable parameters. The ARC Management system can be adjusted with the front panel or with the digital interfaces. With this compact HV power supply, an ARC is defined for any output current Iout ≥ 1.5. Iset. Iset is the set current. The functionality of ARC management can be divided into three operating states:

KillEnable active

- High voltage shuts down after the first ARC

Enable ARC counting

- The high voltage is restored immediately after every ARC,

- The ARCs are counted,

- The high voltage is shut down if the allowed number of ARCs (ARCnumber) in a specific time (ARCTime) is exceeded.

Disable ARC counting

- High voltage is shut down after every ARC,

- After the ARC wait time (ARC-Wait) high voltage is ramped to the set voltage with the ARC-Ramp,

- ARC-Wait and ARC-Ramp are factory fixed settings to avoid damage due to permanent ARCs.

350 W RANGE

- Voltage from 1 kVOLT to 70 kVOLT

- 350 W power

- Current from 5 mA to 350 mA

- 1 channel high voltage power supply

- Positive (+) or negative (-) polarity, fixed

- Common ground (GND)

- Voltage and current control by digital encoder

- Voltage and current measurement by 12-line multi-line LCD

- Safety inhibit in analog mode 0 – 5 V

- Programmable voltage ramp 800 V / s

- GES or proprietary connector on rear panel

- Serial USB and CANbus interfaces

- Optional Ethernet interface

- Model L / W / H mm: 280, 254, 107