HIGH VOLTAGE CONNECTORS AND CABLES

PHYSICAL Instruments offers a wide range of high-voltage connectors, high-voltage shielded coaxial and unshielded cables from our supplier HIVOLT.de, as well as a very high quality assembly and crimping service. Download our full catalog here.

IF YOU CANNOT FIND YOUR REFERENCE, PLEASE CONTACT US.

HIGH VOLTAGE CABLES

Our range of high voltage connectors and cables from our supplier HIVOLT.de is recommended for a variety of applications, including:

- High voltage electronics and wiring of power boxes,

- Test benches,

- Scientific analysis instruments,

- Transmission of electrical signals,

- High voltage measurement,

- High energy physics and particle accelerator techniques,

- Industrial, nuclear, medical and military electronics,

- Laser systems,

- Welding by electron gun,

- …

WARNING

Many applications suggest that the operating regime is continuous (DC), but in reality the cable is subjected to a pulsed transient regime. In this case, it is necessary to use AC configuration cables to ensure the electrical safety of your equipment and to provide better cable longevity. Please ask us for additional advice.

WARNING

High voltage cables without AC indication must not be used with AC voltage. The term AC designates an effective sinusoidal voltage (RMS) at a frequency of 50/60 Hz. The other alternative forms must be studied individually. Please ask us for additional advice.

SELECTION OF YOUR HIGH VOLTAGE CABLE

- What is your application?

- What is the operating voltage? (DC, AC, pulsed DC)

- If AC: rms, peak, peak-peak?

- If AC or DC pulsed: What is the frequency?

- What is the operating current?

- What is the maximum outside diameter?

- What is the maximum dielectric diameter?

- How will the cable be connected? If with connectors, what types of connectors?

- What is the operating temperature?

- Is it a flexible / mobile or fixed installation?

- Are there any other special requirements?

UNIPOLAR HIGH VOLTAGE CABLE CONSTRAINTS

During its lifetime, the high voltage cable is subjected to various stresses. With our supplier HIVOLT.de we have listed those constraints.

Electrical constraints

The insulation supports intense electric fields under direct, alternating or pulsed voltage. It is therefore important that it is sized to guarantee a very high dielectric strength. Among the destructive modes of action of the insulator, we note the phenomena of electrical arborescence (internal electrical discharges which locally destroy the material by forming cavities), the phenomena of electrochemical arborescence (presence of water, vacuoles and protrusions) which evolve and degrade the high voltage cable slowly over time, partial discharges in the presence of micro cavities in the insulation which lead to internal breakdown and premature wear of the high voltage cable.

Thermal constraints

They arise, among other things, from the heating up of the conductor by the Joule effect and from the external operating temperature. The rise in temperature influences the performance of the insulating function by increasing the dielectric losses and by decreasing the electrical resistivity of the high voltage cable.

Climatic constraints

Climatic aging results from exposure of the high voltage cable to solar radiation, humidity, ambient air, ozone, particles from industrial pollution, etc.

Radiative constraints

They are found in nuclear and medical facilities. In synthetic insulators such as polyethylene and its chemical derivatives, radiation (X-ray, Gamma ray) causes a break in the polymer chain and therefore an irreversible loss of the insulating function of the high-voltage cable.

In summary, additionally to its very specific dielectric characteristics for use in high voltage cables (high dielectric strength and resistivity), the insulating material must have good aptitudes being able to face mechanical vibrations, chemical attacks, it must be fire resistant and must show good resistance to aging, etc.

Together with HIVOLT.de, we ask you to tell us the environment in which you want to use the cables.

HIGH VOLTAGE CABLES : THE MOST COMMONLY USED MATERIALS

The unipolar high voltage cables are made of synthetic insulating materials based on polyethylene and its polymer derivatives. Polyethylene (PE) has the advantage of having a high dielectric strength (kV / mm) and high resistivity (10 exp 16 Ω. M under moderate fields).

The dielectric materials offered in our range of high voltage cables are: polyethylene (PE), cross-linked polyethylene (XLPE), low-density polyethylene (LDHMW PE), Ethylene-Propylene rubber (EPR), Terpolymer rubber of Ethylene, Propylene and Diene (EPDM) and Silicone rubber

Polyvinyl Chloride (PVC)

It is mixed with plasticizers in order to provide an insulating, flammable thermoplastic material, which is insensitive to ozone, but resistant to oils, solvents, acids, little absorbent and humidity. However, the permittivity, the thermal resistance and the dielectric losses are high, which sometimes limits its use for covering high-voltage cables (external jacket).

Polyethylene (PE)

It has remarkable electrical qualities as described in the introduction (dielectric strength of 100 kV / mm), but it oxidizes quickly, it is flammable and not very hygroscopic.

Cross-linked Polyethylene (XLPE)

It is obtained by creating chemical bonds (bridging by carbon-carbon covalent bonds) between the macromolecular chains with the aim of improving the thermal and mechanical characteristics of polyethylene. Its operating temperature in service can exceed hundred degrees Celsius, it is tolerant to overload and short-circuit temperatures, it has good weather resistance. On the other hand, its dielectric properties (loss factor) are less effective compared to PE.

Low Density Polyethylene (LDPE) or Low Density High Molecular Weight Polyethylene (LDHMW PE)

It is obtained from a high pressure process (1000 bar to 3000 bar) and at high temperatures (130 ° C to 350 ° C). Its crystallization is being prevented in the manufacturing process, it has a high purity which allows it to be used in very high voltage cables (> 100 kV). On the other hand, its operating temperature in normal service does not exceed 70 ° C.

Ethylene-Propylene Rubber (EPR) and Ethylene-Propylene-Diene-Monomere – (EPDM)

These are copolymers that have the advantages of good flexibility, excellent resistance against ozone, against weathering, against partial discharges, as well as against ionizing radiation. However, their limitations relate to resistance to chemical attacks (oil) and to the resistance to mediocre flame propagation.

Silicone rubber

It is intended for the manufacturing of special cables for the navy, for aviation purposes, etc. It has a resistance to very high temperatures (- 80 ° C to + 250 ° C) and a remarkable behavior against fire. The combustion of the cable transforms the insulation into silica which preserves the insulating properties. It is extremely flexible, making it a very good candidate for internal fitting operations in electrical racks.

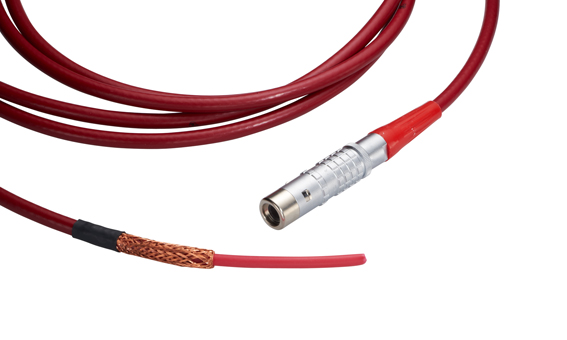

HIGH VOLTAGE CONNECTORS

Our ranges of high voltage connectors include standard models of ‘single pin’ types with a voltage withstanding up to 100 kV. You can also find specific ‘multi-pin’ models up to 6 kV.

Insulators are polytetrafluoroethylene (PTFE) materials commonly called Teflon, polyoxymethylene (POM) or Delrin.

We work with the brands RADIALL, ROSENBERGER, LEMO, GES and REDELL and we help you make the best choice according to your application and your work environment.

In addition, all the references mentioned above are mounted on a very large number of high-voltage devices that we sell, such as high-voltage DC / DC converters, high-voltage AC / DC power supplies, high-voltage amplifiers and generators as well as the high voltage pulse generators.

ASSEMBLY OF HIGH VOLTAGE CABLES / HIGH VOLTAGE CONNECTORS (CRIMPING) / Service by HIVOLT.de

We complete our range of high voltage connectors and cables by offering a very high quality assembly and crimping service that we arrange with one of our long-standing partners HIVOLT.de in Germany.

The assembly with the connector requires very great care. In particular in alternating sinusoidal and / or pulsed mode. One must avoid air layers at the various interfaces (conductor / dielectric insulator / shielding). The layers of air induce partial breakdowns / discharges with a risk of damaging the connector and the high-voltage cable.

In order to guarantee you an impeccable quality, crimping tests are offered after the assembly. They consist of putting the assembly under high voltage for a while. Assemblies are tested in Germany to our partner HIVOLT.de.